3D printing, a game-changer in manufacturing, transforms digital designs into tangible objects layer by layer. It's not just for tech enthusiasts; it's revolutionizing industries.

From aerospace to healthcare, these machines are making waves. This article explores what 3D printing is and its significant impact on various industries.

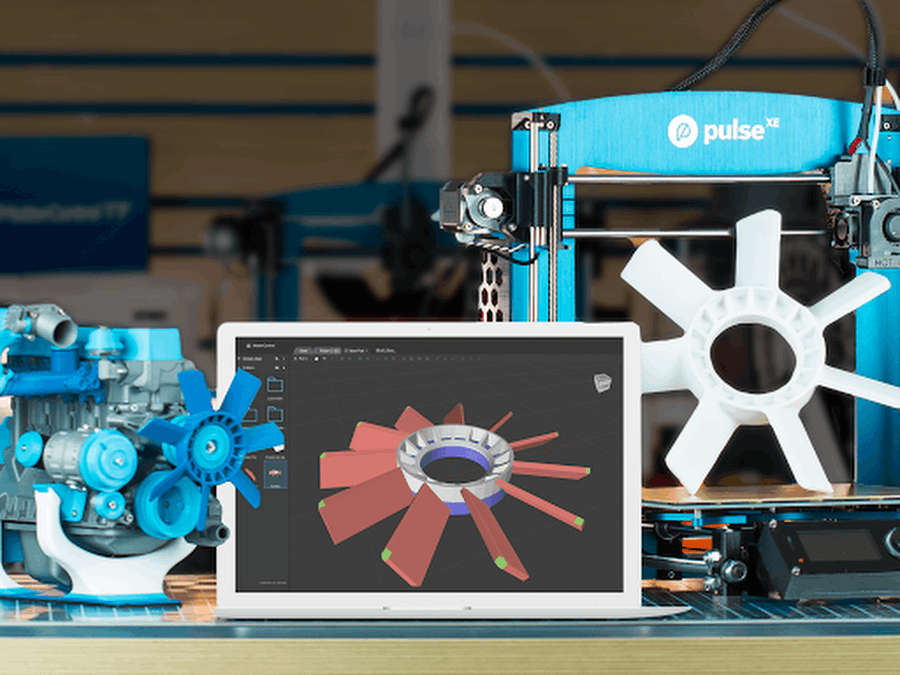

Basics of 3D Printing: How it works

This technology is a process that creates physical objects from digital designs. It works by layering different 3D printing materials, like plastic or metal.

A 3D printer reads a digital file and deposits material layer by layer, following the design's shape. This builds the object from the bottom up. It's used in many fields, from medical to automotive.

This technology has applications across various industries, including healthcare, aerospace, and consumer goods, allowing for rapid prototyping and complex custom designs.

Popular 3D printing machine models encompass a range of technologies and applications:

- Selective Laser Sintering (SLS): A key player in SLS technology is the EOS P 396, known for its precision and ability to print complex geometries. SLS printers are favored in professional settings for their high-quality output.

- Stereolithography (SLA): The Formlabs Form 3 is a highly regarded model in the SLA category. It is known for its fine detail, accuracy, flexible 3D prints, and smooth surface finish, making it popular for prototypes and detailed models.

- Lithophane Makers: For creating lithophanes, printers like the Creality Ender 3 are popular due to their affordability, accessibility, and ease of use. These printers are suitable for both hobbyists and enthusiasts.

- Octoprint Compatible Printers: The Prusa i3 MK3S+ is highly regarded for its compatibility with OctoPrint, a software that allows for enhanced printer control and monitoring.

Each of these printers serves different aspects of the industry, from industrial-grade production to personal and educational use, reflecting the diverse applications of 3D printing services.

Impact of 3D Printing in Different Industries

Three-dimensional printing's impact across industries is massive:

3D Printing in Healthcare: Custom implants, prosthetics

In healthcare, 3D printing is a big deal. It's used for custom implants and prosthetics, tailored to individual patients. These custom implants fit better and work more efficiently.

Prosthetics made using this method are cheaper and faster to produce. They're also more accessible, especially for children who outgrow them quickly.

The technique is also used for surgical planning and creating models for education and practice.

Aerospace Applications: Building lighter, stronger parts

In aerospace, this technique is a game-changer. It's used to build lighter, stronger parts, crucial for aircraft and spacecraft. This means improved fuel efficiency and performance.

Aerospace companies are utilizing 3D printing to create components that are not only lighter but also structurally sound, enhancing the overall safety and functionality of aircraft and spacecraft.

This process makes complex designs impossible with traditional methods. It also speeds up production and reduces waste, making it a sustainable choice.

Impact on Manufacturing: Faster, cost-effective production

In manufacturing, we see this printing as a powerhouse. It speeds up production and cuts costs. You get faster prototyping, so new products hit the market quicker.

The ability to produce complex parts without the need for expensive tooling or molds is another major advantage, allowing for more creative and intricate designs at a lower cost.

Additionally, 3D printing contributes to a reduction in material waste and can be more energy-efficient compared to traditional manufacturing methods, aligning with an emphasis on sustainability.

3D Printing in Education: Teaching hands-on engineering

In education, print in 3D is a hands-on tool. It's used in teaching engineering and design. Students can create models, test ideas, and learn about manufacturing processes.

This direct involvement in the creation and testing of models fosters critical thinking, creativity, and problem-solving skills. This technology is also being utilized in other disciplines.

It boosts creativity and problem-solving skills. It is also great for STEM education, making complex concepts more tangible and easier to understand.

Automotive: Rapid prototyping, complex part production

In the automotive industry, these machines are a key player. It's used for rapid prototyping - car parts are designed and tested quickly. This speeds up the development process.

Also, it allows for producing complex parts that would be hard or expensive with traditional methods. It's making car manufacturing more efficient and innovative.

This capability allows for more innovative design and customization in vehicles, contributing to advancements in automotive engineering and design.

Future Trends: Where is 3D printing heading?

The future trends in 3D printing companies indicate an evolving landscape with exciting advancements:

- Development of New Materials: Research is ongoing into new, more durable, and flexible materials, expanding the applications of this technology.

- Increased Printing Speed: Efforts are being made to enhance the speed of this service, making it more viable for mass production and large-scale projects.

- Large-Scale 3D Printing: Advancements are being made in printing larger structures, including potential applications in construction and housing.

- Bioprinting Advancements: Progress in bioprinting, including the potential to print organs and tissues, could revolutionize medical treatments and transplants.

- Sustainability Efforts: Focus on using more sustainable, eco-friendly materials and processes to reduce environmental impact.

- Integration with AI and Machine Learning: Enhanced design, troubleshooting, and optimization of printing processes through AI technologies.

- Wider Industrial Adoption: More industries are expected to adopt this mechanic for various applications, from electronics to energy sectors.

- Personalization and Customization: Continued growth in the demand for customized and personalized products, supported by the flexibility of 3D printing.

These trends suggest a future where 3D printing is more integrated into manufacturing processes, offering increased efficiency, customization, and revolutionary applications in various fields.

Conclusion

3D printing technologies are transformative. It's revolutionizing industries, from healthcare to aerospace. It allows for customization, complex designs, and rapid prototyping, cutting costs and time.

Its future is promising, with advancements in materials, speed, and applications. It's not just a niche tool; it's becoming integral in manufacturing, education, and beyond.

The widespread adoption and continuous improvement of these new technologies indicate their growing significance and potential to further reshape industries and practices.